Introduction

Sequencing plasmid DNA is key to the development of biologic drug manufacturing. As the demand for high-throughput biologics management in drug discovery escalates, the urgency to simplify and automate plasmid production grows. Despite the process having well-defined steps,1 automation raises concerns about maintaining quality. The inclusion of full plasmid sequencing, as opposed to sequencing only the insert, adds a higher level of certainty to the results, but it also increases the complexity of the process. This raises important questions: is it possible to automate every stage while ensuring consistent quality? If feasible, what form should these automated systems take?

Advantages of Automation

The secret to effective automation lies in reliable, effective, and quality-centric processes that reduce errors typically found in manual production and enhance multiple volume runs. Some of the benefits of successful automation include:

- Better sample tracking

- Reproducibility

- Higher throughput

The manual process of preparing large quantities of plasmid DNA for downstream processes is time-consuming, physically demanding, and error-prone, especially as sample throughput increases. Nonetheless, through optimizing several modules, it’s possible to implement an automated high-throughput plasmid DNA production pipeline.2

However, automation comes with its own set of obstacles.

Challenges Facing High-Throughput Plasmid Production

Plasmid sequencing involves multi-step protocols and each manual step must be optimized for the automation platform, which may also require adjusting upstream and downstream steps. While automation technologies excel at optimizing individual steps, the inherent complexity of the plasmid DNA production pipeline presents a significant hurdle. Any disruption or error within this pipeline could compromise the final product, rendering test results invalid. Therefore, careful optimization and validation of each automated component are essential to ensure seamless integration and maintain quality throughout the process.

For instance, manual plasmid purification reduces delays between process steps. In contrast, automated platforms may introduce periods where samples remain idle on the robotic deck. This delay could impact quality; however, extensive testing has shown that plasmid stability is unaffected even after extended periods (7-16 hours) of deck incubation.2

Certain steps within the plasmid production workflow, such as transformation, inoculation, and colony picking, necessitate a linear sequence. Fortunately, subsequent steps like culture expansion and purification can be strategically parallelized with plasmid sequencing. This approach, often utilizing rolling circle amplification (RCA) from the same colonies employed in culture expansion, enables simultaneous sequence confirmation and reagent generation.3

By implementing this strategic synergy between parallel processing and automation, it becomes possible to achieve both accurate plasmid sequence verification and efficient production of purified material. This streamlined approach represents a significant advancement in the realm of plasmid-based reagent management.

Simplifying NGS Library Preparation with ExpressPlex

Traditional library preparation methods often require multiple incubation periods and cumbersome pipetting steps, resulting in lengthy workflow times. Fortunately, seqWell’s innovative ExpressPlex™ library prep technology provides a solution to this challenge.

ExpressPlex can automate protocols by cutting workflows to just 90 minutes. The simplicity of this workflow makes it uniquely suited for manual, automated, and miniaturized library prep from plasmids and PCR products.4 Additionally, ExpressPlex is compatible with RCA, allowing for fast multiplexing of hundreds of samples. (For a deeper understanding of why ExpressPlex is well-suited for manual, automated, and ultra-high throughput library prep from plasmids and PCR products, watch our webinar.) Now, with an HT 384-well ultra-high throughput version (ExpressPlex HT), researchers can further increase their throughput and accelerate their work. With ExpressPlex freeing up valuable time from library preparation, they can focus on what really matters—data analysis and outcome interpretation.

Combining Automation and ExpressPlex Library Prep

The dual requirements of reduced turnaround time and higher multiplexing demand highly efficient NGS library prep methods and reliable, easy-to-implement automated liquid handling systems.

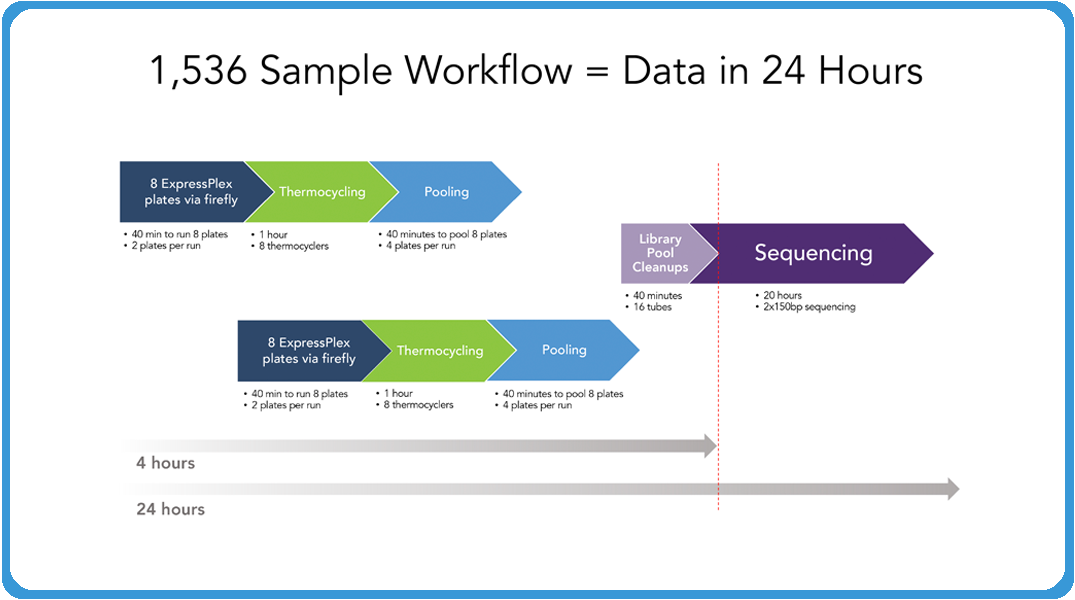

For example, the automation of ExpressPlex Library Preparation Kit on SPT Labtech’s firefly® liquid handler creates a compact and cost efficient method for fast screening of synthetic constructs.5 Using the ExpressPlex Library Prep Kit, the SPT Labtech firefly, and thermocyclers, a single user can prepare 1,536 total libraries and take them through sequencing in 24 hours.

The automation of seqWell’s ExpressPlex Library Preparation Kit has also been used with the Tecan Fluent® liquid handler for fast screening of synthetic constructs.6 In this case, 96 libraries were prepared on the Tecan Fluent and 96 libraries were prepared manually. ExpressPlex libraries created on the Tecan Fluent were found to be highly consistent, maintaining highly balanced read counts without manual normalization. Using the ExpressPlex Library Preparation Kit, the Tecan Fluent, and sufficient thermocyclers, a single user can prepare 1,536 total libraries and take them through sequencing in 24 hours.

In another study, automated preparation of libraries using the ExpressPlex Library Kit on the Opentrons Flex robotic system was compared with manual preparation.7 The results showed that preparing ExpressPlex libraries using the Flex liquid handler significantly reduced turnaround time and increased throughput. Automated multiplexed library prep yielded robust sequencing performance with higher molarity and over 95% of reads about the pass filter threshold when compared to the manual process. Automating the ExpressPlex library prep workflow supports an end-to-end workflow from extracted plasmid/amplicon DNA to data generation within 24 hours.

Conclusion

Fast and reproducible sequencing of synthetic construct libraries has emerged as a powerful tool that enables synthetic biology researchers to rapidly determine if their sequences of interest are present. This advancement has transformed high-throughput labs, enabling them to screen large quantities of constructs with ease and concentrate on the important discovery aspects of their research.

At seqWell, we continue to develop ways to improve the quality and scale of NGS-based plasmid sequencing pipelines.1 ExpressPlex greatly cuts workflow times allowing you to spend your time on data and results.

References

- https://seqwell.com/the-need-for-high-throughput-ngs-based-plasmid-sequencing/

- https://www.sciencedirect.com/science/article/pii/S247263032201439X

- https://genome.cshlp.org/content/11/6/1095.full

- https://seqwell.com/wp-content/uploads/2024/01/SW2024_Ultra-High-Throughput-Sequencing-Flyer-OL-8.5×11-Fin.pdf

- https://seqwell.com/wp-content/uploads/2023/06/SW2023_ExpressPlex-SPT-AN-07182023.pdf

- https://seqwell.com/wp-content/uploads/2023/09/SW2023_ExpressPlex-Tecan-AN-09072023.pdf

- https://seqwell.com/wp-content/uploads/2024/01/Mulitplexed-Prep-Plasmid-Libraries_PAG-2024_V5.pdf